Benefits of Using Alum

If you run a poultry farm, you can experience these advantages by using alum as poultry litter amendment (1):

- Reduced ammonia levels in the poultry house.

- Decreased pathogen levels in litter and on birds.

- Improved bird performance (due to less ammonia and fewer pathogens).

- Lowered energy costs because you need less ventilation to remove ammonia.

- Increased nitrogen content in the litter.

- Reduced quantities of water-soluble phosphorus.

Treated Litter vs. Untreated Litter

In theory, alum applications only have an impact on the forms and water solubility of phosphorus (P) in poultry litter, not the total phosphorus mass in the litter.

In theory, alum applications only have an impact on the forms and water solubility of phosphorus (P) in poultry litter, not the total phosphorus mass in the litter.

For instance, in a poultry barn containing 20 tons of litter with a P concentration of 1.3%, the total amount of P is 520 lbs. If litter is amended with alum at a rate of 10% by weight, the total amount of P in the barn remains unchanged at 520 lbs. However, the concentration of P in the alum treated litter will decrease by 10% due to simple dilution with alum.

Using the same example, a 10% alum application will change the P concentration from 1.3% (26 lbs P/ton or 59.5 lbs P2O5/ton) to 1.17% (23.4 lbs P/ton or 53.6 lbs P2O5/ton), a small decrease in P concentration. When obtaining litter on a mass basis (i.e., equal tonnage), alum litter purchases will result in slightly less P compared to normal litter.

Another way to think of this is that it would require slightly more alum-treated litter than normal litter in applying equal amounts of total P and other nutrients to a field. (1)

Safety Precautions for Using Alum

The acidic nature of alum requires it to be treated with care and caution, similar to all acids. Applicators should always wear goggles for eye protection and a dust mask to avoid breathing alum dust, particularly if a spreader is used that broadcasts the material. Gloves should also be worn when handling alum to prevent skin irritation. The acid in alum will be neutralized in the litter after two to four weeks, depending on the application rate. Thus, there are no precautions needed for handling the litter at cleanout. Minimize exposure of equipment and footings to alum since acids are corrosive to metal surfaces.

Growers should also be aware that application of alum to the litter does not mean that ventilation can be completely ignored. Since birds generate a great deal of moisture throughout the life of the flock, it is essential that producers provide the required minimum ventilation from day one so that moisture buildup in the house is prevented.

Pure7: An Alum Backed by Poultry Industry Experience

As a poultry farmer, you need any edge you can get to achieve higher production and better quality at a lower cost, while protecting your workers and minimizing environmental impact.

Using Pure7 for poultry litter management can help you get that edge. Here are the benefits you can expect from Pure7:

- Reduced ammonia emissions. Improves safety for your workers. You also get heavier birds, better feed conversion, and lower mortality.

- Reduced pathogen levels. Improves bird health and food safety.

- Reduced propane use. Less ventilation required for ammonia control in cooler months.

- Higher crop yields. Increased nitrogen content in the litter boosts plant growth.

- Reduced pollution. Better binding of phosphorus reduces phosphorus runoff from fields fertilized with poultry litter.

A better alternative

A better alternative

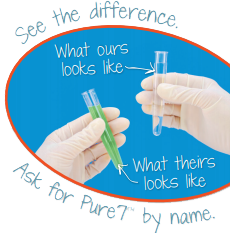

Pure7 is purified aluminum sulfate blended with a higher acid content for use in poultry production facilities. Pure7 is 100% low iron, and, unlike standard-grade alum products, it is free of many other heavy metals including arsenic, copper, mercury, lead, zinc, and more. You can see it in the color difference – Pure7 is crystal-clear, while standard products have a green to brown tint. With ever-increasing environmental regulations, it is a good idea to use as few heavy metals as possible in your operations.

Affinity Chemical’s Pure7 team includes individuals who were part of the original research into alum use as a poultry litter amendment, as well as those who have considerable alum production experience.

We manufacture Pure7 in the U.S. with equipment dedicated to its production. We never mix our product after the fact or during transportation – that’s why you receive a consistent product, with no variations from one delivery to the next.

Pure7 is distributed exclusively by Clear View Enterprises, a leader in the animal health products industry who developed the market for litter amendments.

Like all chemicals, Pure7 needs to be handled in a safe manner. Read about safe handling and other safety information of Pure7 on the safety data sheet.

Get the Pure7 Edge

Treating litter with Pure7 is a cost effective, best management practice for your poultry farm. Interested in learning more about using Pure7?

References